Products

-

- Hydraulic Shear - Pile Hammer - Pile Breaker - Hydraulic Breaker - Orange Peel Grapple - Backhoe Loader Excavator Attachment

Excavator Attachment -

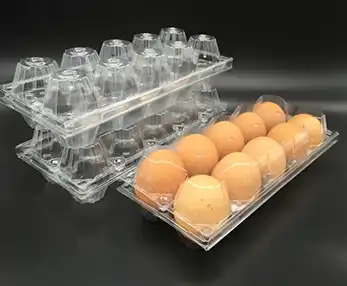

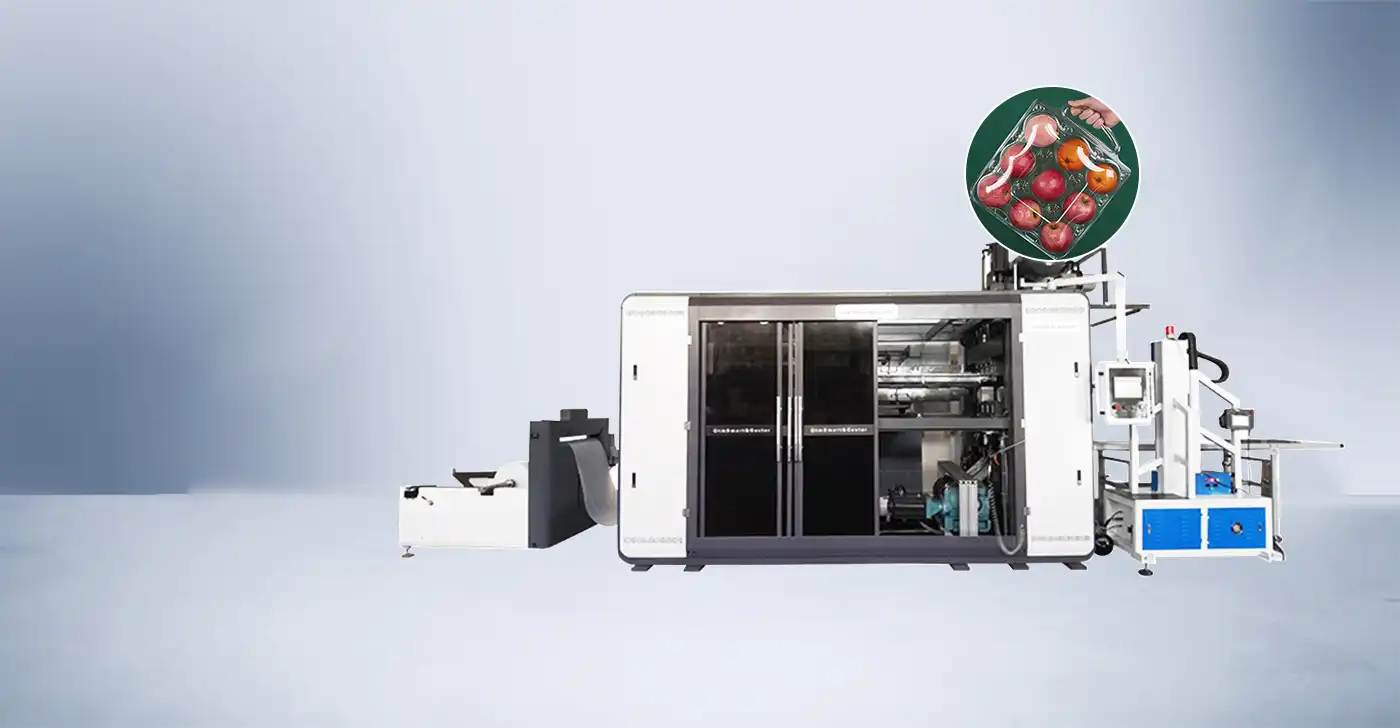

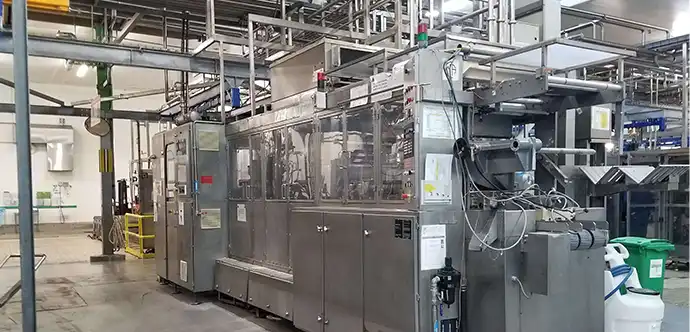

- Thermo Forming Machine - Plastic Injection Molding Machine - Shoe Injection Moulding Machine - Bottle Blowing Machine Plastic Products Equipment

Plastic Products Equipment -

- Fog cannon Machine - Hydroseeding Machine - Snow Sweeper Machine Environmental Protection Equipment

Environmental Protection Equipment

Construction Machinery

Construction Machinery

Paper Product Equipment

Paper Product Equipment Cutting Equipment

Cutting Equipment

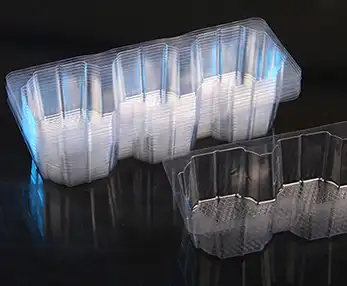

Raw materials: PP, PS, HIPS, PET, PVC, PLA, etc.

Raw materials: PP, PS, HIPS, PET, PVC, PLA, etc.

Wire Saw Machine

Wire Saw Machine

Email: admin@yugongmachine.com

Email: admin@yugongmachine.com

Whatsapp: +8615937192512

Whatsapp: +8615937192512